Questions and Answers - FAQ

A base of useful knowledge in the field of Off-Grid and Energy Storage.

What are Lithium Cells/Batteries

Lithium (Li-ion) cells are a type of battery that is often used in many electronic devices such as mobile phones, laptops, cameras and electric cars. Lithium cells are very popular due to their high energy-to-weight concentration, low ignition potential, and long maintenance-free intervals.

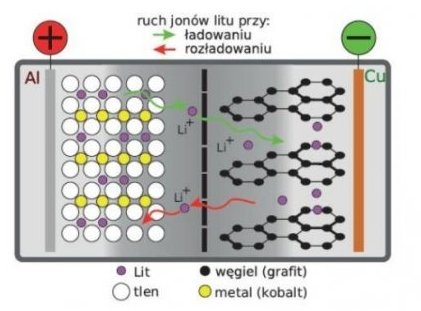

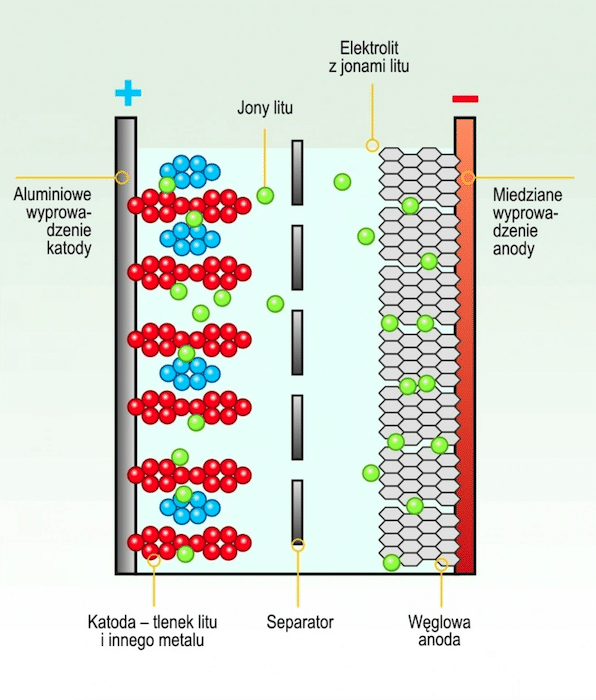

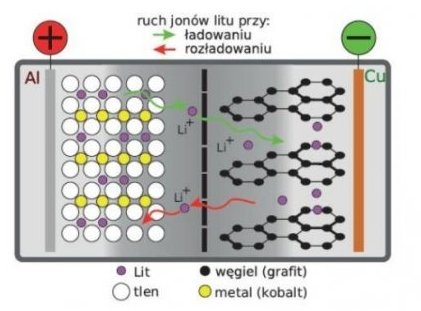

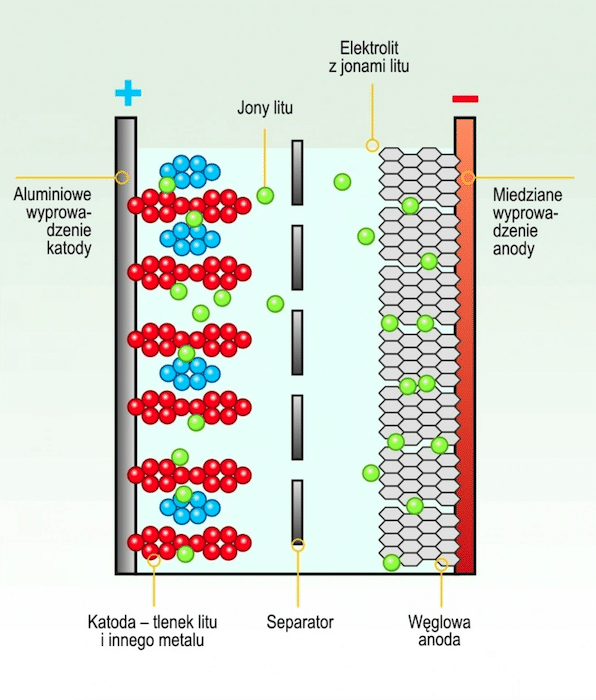

Lithium cells consist of electrodes - an anode and a cathode - between which electricity flows. The electrodes are made of materials with different electrochemical potentials, which allows them to store and release energy. The electrolyte is responsible for the transfer of lithium ions between the electrodes during charging and discharging of the cell.

Lithium cells also have a low self-discharge, which means they maintain their energy capacity for a long period of time, even when they are not in use. In addition, lithium cells are usually readily available and easy to manufacture, making them attractive for a wide variety of applications.

It is worth remembering, however, that lithium cells require proper care and handling to ensure their safety and durability. For example, some types of lithium cells may be subject to excessive discharge, which may lead to cell damage or dangerous phenomena such as self-ignition. Therefore, it is important to follow the manufacturer's recommendations for charging and storing lithium cells.

Lithium cells consist of electrodes - an anode and a cathode - between which electricity flows. The electrodes are made of materials with different electrochemical potentials, which allows them to store and release energy. The electrolyte is responsible for the transfer of lithium ions between the electrodes during charging and discharging of the cell.

Lithium cells also have a low self-discharge, which means they maintain their energy capacity for a long period of time, even when they are not in use. In addition, lithium cells are usually readily available and easy to manufacture, making them attractive for a wide variety of applications.

It is worth remembering, however, that lithium cells require proper care and handling to ensure their safety and durability. For example, some types of lithium cells may be subject to excessive discharge, which may lead to cell damage or dangerous phenomena such as self-ignition. Therefore, it is important to follow the manufacturer's recommendations for charging and storing lithium cells.

Types of Lithium Cells (Breakdown)

Lithium cells can be divided into several main types depending on their chemical structure and materials used:

1. Lithium-ion (Li-ion) cellsare a type of chemical battery in which the transfer of lithium ions occurs between the anode and cathode electrodes. During charging, lithium ions move from the cathode to the anode, and during discharge, lithium ions move from the anode to the cathode. Lithium-ion cells have a high energy density, which means they deliver a lot of energy in a small area. They are commonly used in electronic devices such as laptops, smartphones and electric cars due to their high efficiency and reliability. lithium ions.

2. Lithium-polymer cells (Li-Poly) are a type of lithium battery in which the electrolyte is encapsulated in a polymer matrix. Unlike traditional lithium-ion batteries, where the electrolyte is liquid, lithium-polymer batteries encapsulate the electrolyte in a plastic matrix for greater safety and flexibility. Lithium polymer cells are used in many portable devices such as smartphones, tablets and wireless headphones due to their lightness, reliability and high performance.

3 . Lithium metal cells (Li-Metal) are a type of lithium battery where the anode is made of pure lithium or another lithium metal. They are considered to be one of the most efficient lithium batteries because lithium is one of the most electron-capacity metals. Lithium metal cells have a high voltage, high capacity and fast charging rate. However, their use is limited by their short lifespan and the potential safety risks associated with the rapid oxidation of lithium. They are often used in high power applications such as electric cars and power tools.

4. Lithium Carbon (Li-C) cells are a type of lithium cell that uses carbon as the anode and lithium as the cathode. In the process of charging and discharging, lithium ions move between the anode and cathode, and electrons are moved through external circuits. As a result of these processes, Li-C cells achieve a high energy density and a long lifetime of charging and discharging cycles. Li-C cells are often used in applications such as automotive batteries and energy storage systems.

These cells have a high energy density and low resistivity, making them often used in high power applications such as such as electric cars, portable electronics and energy storage. The types of lithium-carbon cells include, among others: carbon cells (LiCoO2), graphite cells (LiC6) and silicon cells (LiSi).

5. Lithium-sulphur (Li-S) cellsare a type of lithium cell where metallic lithium is the anode and sulfur is the cathode. The electrolyte is a solution of lithium salts.

5. Lithium-sulphur (Li-S) cellsare a type of lithium cell where metallic lithium is the anode and sulfur is the cathode. The electrolyte is a solution of lithium salts.

1. Lithium-ion (Li-ion) cellsare a type of chemical battery in which the transfer of lithium ions occurs between the anode and cathode electrodes. During charging, lithium ions move from the cathode to the anode, and during discharge, lithium ions move from the anode to the cathode. Lithium-ion cells have a high energy density, which means they deliver a lot of energy in a small area. They are commonly used in electronic devices such as laptops, smartphones and electric cars due to their high efficiency and reliability. lithium ions.

Types of lithium-ion cells include:

- LiCoO2 cells - with lithium anode and LiCoO2 cathode

- LiFePO4 cells - with lithium anode and LiFePO4 cathode

- LiMn2O4 cells - with lithium anode and LiMn2O4 cathode

- NMC (LiNiMnCoO2) cells - with lithium anode and LiNiMnCoO2 cathode

- NCM (LiNiCoMnO2) cells - with lithium anode and LiNiCoMnO2 cathode

2. Lithium-polymer cells (Li-Poly) are a type of lithium battery in which the electrolyte is encapsulated in a polymer matrix. Unlike traditional lithium-ion batteries, where the electrolyte is liquid, lithium-polymer batteries encapsulate the electrolyte in a plastic matrix for greater safety and flexibility. Lithium polymer cells are used in many portable devices such as smartphones, tablets and wireless headphones due to their lightness, reliability and high performance.

Lithium-polymer cells are one of the most popular types of lithium cells. They can be divided into several main types:

- Lithium-polymer cells based on electrolytic polymers (e.g. PEO and PPO polymers)

- Lithium-polymer cells based on electrolytic polymers based on compact electrolytes (e.g. electrolytic gel) Lithium-polymer cells based on nanocomposites (e.g. cells with graphene nanotubes and polymer electrolyte)

3 . Lithium metal cells (Li-Metal) are a type of lithium battery where the anode is made of pure lithium or another lithium metal. They are considered to be one of the most efficient lithium batteries because lithium is one of the most electron-capacity metals. Lithium metal cells have a high voltage, high capacity and fast charging rate. However, their use is limited by their short lifespan and the potential safety risks associated with the rapid oxidation of lithium. They are often used in high power applications such as electric cars and power tools.

Types of lithium metal cells include:

- Li-Metal cells with pure lithium anode

- Li-Metal cells with lithium and other lithium metal anodes

- Li-Metal cells with lithium alloy anode

4. Lithium Carbon (Li-C) cells are a type of lithium cell that uses carbon as the anode and lithium as the cathode. In the process of charging and discharging, lithium ions move between the anode and cathode, and electrons are moved through external circuits. As a result of these processes, Li-C cells achieve a high energy density and a long lifetime of charging and discharging cycles. Li-C cells are often used in applications such as automotive batteries and energy storage systems.

These cells have a high energy density and low resistivity, making them often used in high power applications such as such as electric cars, portable electronics and energy storage. The types of lithium-carbon cells include, among others: carbon cells (LiCoO2), graphite cells (LiC6) and silicon cells (LiSi).

5. Lithium-sulphur (Li-S) cellsare a type of lithium cell where metallic lithium is the anode and sulfur is the cathode. The electrolyte is a solution of lithium salts.

5. Lithium-sulphur (Li-S) cellsare a type of lithium cell where metallic lithium is the anode and sulfur is the cathode. The electrolyte is a solution of lithium salts.Number of Cycles - What Lithium Cells Can Do

Certainly, when looking for Lithium cells for your energy storage, or for applications in smaller packages such as power tools or electric bicycles / scooters, etc., you came across the concept of the life of a given cell defined in cycles.

In short, this means that a given cell and the specific chemistry used in this cell will provide us with a certain number of cycles before the cell loses its parameters.

Of course, manufacturers always add a record that only under the condition of working in appropriate conditions (temperature, humidity) and with certain parameters ( current and voltage)

It is known that in practice it looks different, therefore a cell with a declared number of cycles of 500 can decorate only 100 such cycles, or it can do them equally well and 10,000,000.

What causes it and what affects the number of cycles that the cell can perform:

1. Type of cell, This is determined by the chemistry of which the cells are made, for example:

- Li-ion cells 18650 500-1000 cycles

- NCM cells 1500-2000 cycles

- LiFePo4 cells 4000-9000 cycles

- LTO cells 30 000-40 000 cycles

So, as you can see, the type of chemistry has a diametrical impact on the number of cycles, I recommend this article for exploring the topic because it is mega extensive:< br>

https: //ep.com.pl/files/11011.pdf

2. Operating Conditions, if your cells will work in conditions where the temperature will exceed that specified by the manufacturer, the life of the cells is drastically reduced.

Additionally, all versions of lithium cells (except LTO) do not tolerate charging them at temperatures below 0 Cells can be discharged even at -30 degrees, but an attempt to charge them in the cold ends with irreversible damage or loss of capacity and life.

3. Operating parameters, here we have two most important parameters:

- Intensity, each manufacturer has provided for a specific cell the recommended discharge and charging current referred to as "xC".

Where x is the capacity of the cell, to illustrate this I will write some examples, based on a cell with a capacity of 50Ah.

1C = current 50A

2C = current 100A

3C = current 150A

0.5 C = 25A current

The manufacturer provides information for a 50Ah cell that it can be charged with 0.5C (25A) current and discharged with 2C (100A) current.

Now, if we exceed these parameters, we risk premature wear of the cell, and even fire or explosion.

At the same time, it is worth adding that by maintaining much lower values than recommended by the manufacturer, we increase the safety of use of the cell, and extend its life, and instead of 500 cycles, the cell will perform more of these cycles.

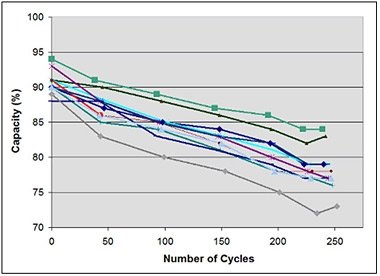

- Voltage,nothing in lithium cells affects the life and safety of use. Cells that operate in a lower voltage range than those provided by the manufacturer will serve us much longer, and increase the safety of use.

Unfortunately, the disadvantage is that lowering the voltage affects the capacity of the cell, and for example, I will give a cell 18650 Li-ion:

2.5V to 4.2V = 100% capacity

2.5V to 4.1V = 90% capacity

2.5V to 4V = 80% capacity

3.35V to 4V = 70% capacity

Personally, in both my magazines I work in the range of 3.35V (because tests have shown that below this voltage the capacity is already marginal) to a maximum of 4V. As a result, my warehouse lost about 28% of its capacity in favor of itextending the service life and increasing safety.

The test performed on LG LGX E78 cells illustrates it very nicely, I invite you to familiarize yourself with my material:

https://youtu.be/2seCekWLvTM

The topic is very extensive, so I recommend see this article which explains this phenomenon very nicely,

https://batteryuniversity.com/article/bu-808-how-to-prolong-lithium-based-batteries

In short, this means that a given cell and the specific chemistry used in this cell will provide us with a certain number of cycles before the cell loses its parameters.

Of course, manufacturers always add a record that only under the condition of working in appropriate conditions (temperature, humidity) and with certain parameters ( current and voltage)

It is known that in practice it looks different, therefore a cell with a declared number of cycles of 500 can decorate only 100 such cycles, or it can do them equally well and 10,000,000.

What causes it and what affects the number of cycles that the cell can perform:

1. Type of cell, This is determined by the chemistry of which the cells are made, for example:

- Li-ion cells 18650 500-1000 cycles

- NCM cells 1500-2000 cycles

- LiFePo4 cells 4000-9000 cycles

- LTO cells 30 000-40 000 cycles

So, as you can see, the type of chemistry has a diametrical impact on the number of cycles, I recommend this article for exploring the topic because it is mega extensive:< br>

https: //ep.com.pl/files/11011.pdf

2. Operating Conditions, if your cells will work in conditions where the temperature will exceed that specified by the manufacturer, the life of the cells is drastically reduced.

Additionally, all versions of lithium cells (except LTO) do not tolerate charging them at temperatures below 0 Cells can be discharged even at -30 degrees, but an attempt to charge them in the cold ends with irreversible damage or loss of capacity and life.

3. Operating parameters, here we have two most important parameters:

- Intensity, each manufacturer has provided for a specific cell the recommended discharge and charging current referred to as "xC".

Where x is the capacity of the cell, to illustrate this I will write some examples, based on a cell with a capacity of 50Ah.

1C = current 50A

2C = current 100A

3C = current 150A

0.5 C = 25A current

The manufacturer provides information for a 50Ah cell that it can be charged with 0.5C (25A) current and discharged with 2C (100A) current.

Now, if we exceed these parameters, we risk premature wear of the cell, and even fire or explosion.

At the same time, it is worth adding that by maintaining much lower values than recommended by the manufacturer, we increase the safety of use of the cell, and extend its life, and instead of 500 cycles, the cell will perform more of these cycles.

- Voltage,nothing in lithium cells affects the life and safety of use. Cells that operate in a lower voltage range than those provided by the manufacturer will serve us much longer, and increase the safety of use.

Unfortunately, the disadvantage is that lowering the voltage affects the capacity of the cell, and for example, I will give a cell 18650 Li-ion:

2.5V to 4.2V = 100% capacity

2.5V to 4.1V = 90% capacity

2.5V to 4V = 80% capacity

3.35V to 4V = 70% capacity

Personally, in both my magazines I work in the range of 3.35V (because tests have shown that below this voltage the capacity is already marginal) to a maximum of 4V. As a result, my warehouse lost about 28% of its capacity in favor of itextending the service life and increasing safety.

The test performed on LG LGX E78 cells illustrates it very nicely, I invite you to familiarize yourself with my material:

https://youtu.be/2seCekWLvTM

The topic is very extensive, so I recommend see this article which explains this phenomenon very nicely,

https://batteryuniversity.com/article/bu-808-how-to-prolong-lithium-based-batteries

I hope that now you will better understand the relationships that result from matching specific chemicals to working conditions and expected storage capacity, which, when properly selected, ensure long and safe operation of the energy storage, or also the package you build.

Can Lithium Cells Be Used in Sub-zero Temperature

Charging and discharging lithium cells in sub-zero temperatures may have some impact on their performance and durability. At low temperatures, the chemical reactions that occur during charging and discharging of the battery may slow down, which may lead to a decrease in battery capacity and performance. In some cases, this can also lead to increased wear on the batteries, which can shorten their lifespan.

Furthermore, low temperatures can also affect battery charging, particularly the charging rate. At low temperatures, chemical reactions can slow down, which can lead to lower current and longer charging times.

To avoid these problems and ensure optimal battery performance and life, it's important to follow the manufacturer's charging recommendations and discharge at sub-zero temperatures. In some cases, the manufacturer may recommend limiting the charging current or limiting the charging time to avoid excessive stress on the battery.

Also, it is worth remembering that charging the battery in sub-zero temperatures can be difficult, as the battery voltage may drop in low temperatures, which may lead to an incomplete battery charge. In these cases, it is important to use the correct charger that is rated to charge the battery in freezing temperatures, and to monitor the condition of the battery while charging to ensure it is fully charged.

Not all lithium cells can be charged in freezing temperatures. Many lithium cells have a limitation in the temperature range at which they can be charged, and some of them are not able to function at temperatures below a certain threshold. If the temperature is too low, the efficiency of the cell may decrease and there is a risk of damage to the battery.

Lithium cells operate based on a chemical reaction between the electrodes inside the battery. At lower than normal temperatures, this reaction is significantly slowed down, which can cause significant drops in battery performance. In some cases, too low a temperature can also cause crystallization of the electrolyte, which can lead to damage to the cell and its irreparable damage.

Therefore, some lithium cells are specially designed to operate in harsh conditions such as freezing temperatures, and are able to function in such conditions without damage. However, these special lithium cells are often more expensive than standard lithium cells and may have lower capacity. /strong>

Furthermore, low temperatures can also affect battery charging, particularly the charging rate. At low temperatures, chemical reactions can slow down, which can lead to lower current and longer charging times.

To avoid these problems and ensure optimal battery performance and life, it's important to follow the manufacturer's charging recommendations and discharge at sub-zero temperatures. In some cases, the manufacturer may recommend limiting the charging current or limiting the charging time to avoid excessive stress on the battery.

Also, it is worth remembering that charging the battery in sub-zero temperatures can be difficult, as the battery voltage may drop in low temperatures, which may lead to an incomplete battery charge. In these cases, it is important to use the correct charger that is rated to charge the battery in freezing temperatures, and to monitor the condition of the battery while charging to ensure it is fully charged.

------ --------------------------------

Not all lithium cells can be charged in freezing temperatures. Many lithium cells have a limitation in the temperature range at which they can be charged, and some of them are not able to function at temperatures below a certain threshold. If the temperature is too low, the efficiency of the cell may decrease and there is a risk of damage to the battery.

Lithium cells operate based on a chemical reaction between the electrodes inside the battery. At lower than normal temperatures, this reaction is significantly slowed down, which can cause significant drops in battery performance. In some cases, too low a temperature can also cause crystallization of the electrolyte, which can lead to damage to the cell and its irreparable damage.

Therefore, some lithium cells are specially designed to operate in harsh conditions such as freezing temperatures, and are able to function in such conditions without damage. However, these special lithium cells are often more expensive than standard lithium cells and may have lower capacity. /strong>

Lithium Titanium (LTO) cells are often regarded as one of the most cold-resistant types of lithium cells. They can be charged at sub-zero temperatures and are often used in applications where harsh environments are required, such as electric cars and industrial equipment.

Ferro lithium phosphate (LiFePO4) cells are also considered to be resistant to low temperatures when discharging and are often used in a variety of applications, unfortunately, attempting to charge them in sub-zero temperatures causes them to be permanently and irreparably damaged.

Taking into account all this information, we do not treat all Lithium cells equally. Also, keep in mind that low temperatures can affect the performance and durability of Lithium cells, so it is important to follow the manufacturer's instructions closely and carefully monitor the condition of the battery during charging/discharging and use. When in doubt, it is best to consult the manufacturer or a lithium battery expert for advice on the best solution.

Designations Used in Lithium Cells

Here is a list of the most popular markings used in energy storage and when determining parameters for lithium cells:

SoH - State of Health - determines the general condition of the cells lithium batteries, i.e. their ability to store energy compared to their initial capacity. SoH is expressed as a percentage and is used to determine when a lithium cell needs to be replaced.

SoC - State of Charge - determines the amount of electricity a lithium cell stores in compared to its maximum capacity. SoC is also expressed as a percentage and is used to determine when lithium cells need to be charged.

DoD - Depth of Discharge - indicates the percentage of electricity that has been consumed from lithium cell in relation to its total capacity. The higher the DoD, the less energy is left in the lithium cell.

EOC - End of Life (End of Charge) is the point where a lithium cell is fully charged and no longer draws charging current . This point is important for proper charging of the lithium cell and can be detected by monitoring the voltage, temperature and/or charging current.

CC - Constant Current - is the charging mode, in which the lithium cell is charged at constant current.

CV - Constant Voltage - is a charging mode in which the lithium cell is charged at constant voltage.

strong>

C-rate - is an indicator that determines the rate of charging or discharging a lithium cell. The C-rate value is equal to the ratio of the charge/discharge current to the capacity of a lithium cell.

IR - Internal Resistance - is a measure of the internal resistance of a lithium cell. The lower the IR value, the less power loss in a lithium cell.

ESR - Equivalent Series Resistance - is the sum of the electrical resistances of all elements connected in series in a lithium cell.< br>

OCV - Open Circuit Voltage(open circuit voltage) - is the voltage generated by a lithium cell when it is not connected to any circuit.

RC - Rate Capacity (nominal capacity) - is the nominal capacity of a lithium cell, expressed in ampere-hours (Ah), which is measured under strictly defined conditions.

Ah - Ampere-hour (ampere-hour) - is a unit of measurement used to express the capacity of a lithium cell, i.e. the amount of energy it can store.

Wh - Watt-hour(Watt-hour) is a unit of electrical energy expressed in volts multiplied by ampere hours. Means the amount of energy that has been consumed or produced by a lithium cell. This is important for monitoring the power consumption and lifetime of a lithium cell.

V - Voltage (Voltage) is the potential difference between two points in an electrical circuit. Indicates the voltage level on the lithium cell and is important for monitoring the state of charge and detecting possible problems with the lithium cell.

I - Current (Current) is the amount of electrical charge that flows through a conductor in unit of time. Indicates the amount of current flowing through the lithium cell and is important for monitoring the state of charge and detecting possible problems with the lithium cell.

mΩ - For lithium cells, mΩ is the unit used to measure the internal resistance lithium cell (also called internal resistance). The internal resistance of a lithium cell is the resistance that occurs inside the cell as a result of current flowing between the cathode and the anode. This is the resistance caused by the resistance of the electrolyte and other internal components of the cell, such as electrodes and connections. Internal resistance can affect cell performance, especially when current flows through the cell during charging and discharging. The value of internal resistance is usually low, only a few millimeters, but it can vary depending on the age of the cell, temperature, charge state and other factors. Measuring the internal resistance of a lithium cell measured in milliohms can help determine cell health and cell performance.

BMS - Battery Management System is a comprehensive system that includes a management module battery and other components and features. It is responsible for monitoring the state of charge, detecting problems with the lithium cell, protecting against damage and ensuring optimal performance and durability of the lithium cell.

Balancer - in lithium cells, it is a device that ensures an even discharge of the battery lithium-ion batteries to increase performance and extend battery life. Lithium-ion cells are prone to unevenness

SoH - State of Health - determines the general condition of the cells lithium batteries, i.e. their ability to store energy compared to their initial capacity. SoH is expressed as a percentage and is used to determine when a lithium cell needs to be replaced.

SoC - State of Charge - determines the amount of electricity a lithium cell stores in compared to its maximum capacity. SoC is also expressed as a percentage and is used to determine when lithium cells need to be charged.

DoD - Depth of Discharge - indicates the percentage of electricity that has been consumed from lithium cell in relation to its total capacity. The higher the DoD, the less energy is left in the lithium cell.

EOC - End of Life (End of Charge) is the point where a lithium cell is fully charged and no longer draws charging current . This point is important for proper charging of the lithium cell and can be detected by monitoring the voltage, temperature and/or charging current.

CC - Constant Current - is the charging mode, in which the lithium cell is charged at constant current.

CV - Constant Voltage - is a charging mode in which the lithium cell is charged at constant voltage.

strong>

C-rate - is an indicator that determines the rate of charging or discharging a lithium cell. The C-rate value is equal to the ratio of the charge/discharge current to the capacity of a lithium cell.

IR - Internal Resistance - is a measure of the internal resistance of a lithium cell. The lower the IR value, the less power loss in a lithium cell.

ESR - Equivalent Series Resistance - is the sum of the electrical resistances of all elements connected in series in a lithium cell.< br>

OCV - Open Circuit Voltage(open circuit voltage) - is the voltage generated by a lithium cell when it is not connected to any circuit.

RC - Rate Capacity (nominal capacity) - is the nominal capacity of a lithium cell, expressed in ampere-hours (Ah), which is measured under strictly defined conditions.

Ah - Ampere-hour (ampere-hour) - is a unit of measurement used to express the capacity of a lithium cell, i.e. the amount of energy it can store.

Wh - Watt-hour(Watt-hour) is a unit of electrical energy expressed in volts multiplied by ampere hours. Means the amount of energy that has been consumed or produced by a lithium cell. This is important for monitoring the power consumption and lifetime of a lithium cell.

V - Voltage (Voltage) is the potential difference between two points in an electrical circuit. Indicates the voltage level on the lithium cell and is important for monitoring the state of charge and detecting possible problems with the lithium cell.

I - Current (Current) is the amount of electrical charge that flows through a conductor in unit of time. Indicates the amount of current flowing through the lithium cell and is important for monitoring the state of charge and detecting possible problems with the lithium cell.

mΩ - For lithium cells, mΩ is the unit used to measure the internal resistance lithium cell (also called internal resistance). The internal resistance of a lithium cell is the resistance that occurs inside the cell as a result of current flowing between the cathode and the anode. This is the resistance caused by the resistance of the electrolyte and other internal components of the cell, such as electrodes and connections. Internal resistance can affect cell performance, especially when current flows through the cell during charging and discharging. The value of internal resistance is usually low, only a few millimeters, but it can vary depending on the age of the cell, temperature, charge state and other factors. Measuring the internal resistance of a lithium cell measured in milliohms can help determine cell health and cell performance.

BMS - Battery Management System is a comprehensive system that includes a management module battery and other components and features. It is responsible for monitoring the state of charge, detecting problems with the lithium cell, protecting against damage and ensuring optimal performance and durability of the lithium cell.

Balancer - in lithium cells, it is a device that ensures an even discharge of the battery lithium-ion batteries to increase performance and extend battery life. Lithium-ion cells are prone to unevenness

Proper IR Measurement in AC/DC Lithium Cells

The internal resistance (IR) of a lithium cell can be measured using two different methods: the DC (Direct Current) method and the AC (Alternating Current) method.

--------------------------

The DC method measures the voltage drop across a lithium cell when a constant current is flowing, typically in the range of 0.1 to 1 A. The internal resistance of a lithium cell is calculated from the voltage and current drop according to Ohm's law.

The AC method consists in measuring the impedance of a lithium cell during the flow of alternating current, usually in the range from 10 Hz to 1 MHz. The impedance of a lithium cell consists of the internal resistance and the capacitance and inductance of the lithium cell. Therefore, in addition to measuring the internal resistance, the AC method can also determine other parameters of the lithium cell, such as capacitance and phase impedance.

Both methods have their advantages and disadvantages. The DC method is simple and cheap to implement, but may miss certain lithium cell problems, such as burnout of the electrodes. The AC method is more accurate and more versatile, but is more expensive and more complicated to implement.

The choice of the measurement method depends on the purpose of the measurement, the available means and the required level of measurement accuracy.

--------------------------

The DC method measures the voltage drop across a lithium cell when a constant current is flowing, typically in the range of 0.1 to 1 A. The internal resistance of a lithium cell is calculated from the voltage and current drop according to Ohm's law.

The AC method consists in measuring the impedance of a lithium cell during the flow of alternating current, usually in the range from 10 Hz to 1 MHz. The impedance of a lithium cell consists of the internal resistance and the capacitance and inductance of the lithium cell. Therefore, in addition to measuring the internal resistance, the AC method can also determine other parameters of the lithium cell, such as capacitance and phase impedance.

Both methods have their advantages and disadvantages. The DC method is simple and cheap to implement, but may miss certain lithium cell problems, such as burnout of the electrodes. The AC method is more accurate and more versatile, but is more expensive and more complicated to implement.

The choice of the measurement method depends on the purpose of the measurement, the available means and the required level of measurement accuracy.

Types of Connections of Lithium Cells

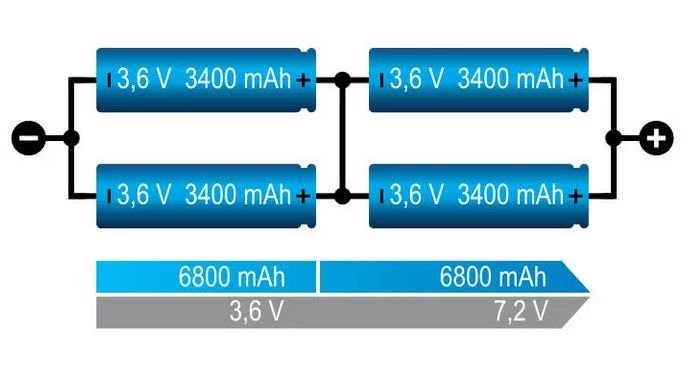

In the case of lithium cells used in multi-cell systems (e.g. in batteries), the connections between them must be properly designed. The types of connections between the cells are:

Note that series connection increases voltage but not capacitance, parallel connection increases capacity but not voltage, but connection series-parallel allows you to achieve the appropriate level of both voltage and capacitance.

- Series connection (series connection) - the fires are connected in such a way that the positive the electrodes of one cell are connected to the negative electrodes of the next cell. In this way, the voltage of the entire system increases, and the capacity depends on the capacity of a single cell.

- Parallel connection parallel connection) - the positive and negative electrodes of the cells are connected to each other in such a way that each cell is connected to the others in parallel. In this way, the capacitance of the entire system increases, and the voltage depends on the voltage of a single cell.

- Series-parallel connection ( series-parallel connection) - it is a combination of the above connections, in which groups of cells are connected in parallel and then in series. This allows you to reach a certain level of voltage and capacity.

Note that series connection increases voltage but not capacitance, parallel connection increases capacity but not voltage, but connection series-parallel allows you to achieve the appropriate level of both voltage and capacitance.

Lithium Cells - Myths

1. Lithium cells require a special charger.

Facts: Lithium cells can be charged with standard chargers available on the market, as long as they are suitable for the type of lithium cell. However, some models of lithium cells require special chargers, so it is important to check the user manual before charging.

------

2. Lithium cells have a memory effect.

Facts: Lithium cells have no memory effect, which means that they do not need to be fully discharged before recharging. In fact, frequent full discharge can shorten the life of lithium cells.

-------

3. Lithium cells cannot provide enough energy.

Facts: Lithium cells can provide enough energy to power various types of devices, including electric cars and home power systems. Their efficiency and capacity are constantly improving, which makes them more and more attractive sources of energy.

------

4. Lithium cells are dangerous and can explode.

Facts: While lithium cells may explode if damaged or overheated, they are safe for home use in most cases. The lithium cells are also designed with safety in mind, with battery management systems that prevent overheating and overvoltage.

------

5. Lithium cells are expensive to buy.

Facts: Lithium cells used to be expensive to buy, but in recent years their price has dropped significantly, making them more affordable for the average consumer. Lithium cells are also more cost-effective in the long run due to their long life and efficiency.

-------

6. Lithium cells are not suitable for use in extreme conditions.

Facts: Lithium cells are used in a variety of conditions, including extreme temperature conditions. Lithium cells are used in power systems for campsites, ships and other places where conditions are harsh. There are also lithium cells that are specially designed for extreme conditions.

-------

7 . Lithium cells must be fully discharged before storage to avoid loss of capacity.

Fact: Lithium cells should be stored approximately 50% charged to avoid loss of capacity. Long-term storage of lithium cells in a fully discharged or fully charged state can lead to damage and loss of capacity.

-------

Facts: Lithium cells can be charged with standard chargers available on the market, as long as they are suitable for the type of lithium cell. However, some models of lithium cells require special chargers, so it is important to check the user manual before charging.

------

2. Lithium cells have a memory effect.

Facts: Lithium cells have no memory effect, which means that they do not need to be fully discharged before recharging. In fact, frequent full discharge can shorten the life of lithium cells.

-------

3. Lithium cells cannot provide enough energy.

Facts: Lithium cells can provide enough energy to power various types of devices, including electric cars and home power systems. Their efficiency and capacity are constantly improving, which makes them more and more attractive sources of energy.

------

4. Lithium cells are dangerous and can explode.

Facts: While lithium cells may explode if damaged or overheated, they are safe for home use in most cases. The lithium cells are also designed with safety in mind, with battery management systems that prevent overheating and overvoltage.

------

5. Lithium cells are expensive to buy.

Facts: Lithium cells used to be expensive to buy, but in recent years their price has dropped significantly, making them more affordable for the average consumer. Lithium cells are also more cost-effective in the long run due to their long life and efficiency.

-------

6. Lithium cells are not suitable for use in extreme conditions.

Facts: Lithium cells are used in a variety of conditions, including extreme temperature conditions. Lithium cells are used in power systems for campsites, ships and other places where conditions are harsh. There are also lithium cells that are specially designed for extreme conditions.

-------

7 . Lithium cells must be fully discharged before storage to avoid loss of capacity.

Fact: Lithium cells should be stored approximately 50% charged to avoid loss of capacity. Long-term storage of lithium cells in a fully discharged or fully charged state can lead to damage and loss of capacity.

-------

Lithium Cells - Facts

1. Lithium cells have a long service life.

Lithium cells have a long service life compared to other types of cells, such as lead-acid. Their performance and capacity remain stable for many years, making them more cost-effective in the long run.

------

strong>2. Lithium cells require special handling during transport.

Lithium cells require special handling during transport due to their unique construction and potential risk of explosion if damaged. Depending on the regulations in your country, there are specific requirements for transporting lithium cells.

------

3. Lithium cells are increasingly popular in automotive applications.

Lithium cells are increasingly popular in automotive applications because they offer higher efficiency and capacity than traditional cells such as lead-acid. Electric cars equipped with lithium fire are more ecological and cheaper to maintain than traditional vehicles with internal combustion engines.

-----

4. Lithium cells are greener than traditional cells.

Lithium cells are greener than traditional cells because they do not contain toxic substances such as mercury, cadmium or lead that are present in other types of cells. In addition, most of the materials used in the production of lithium cells can be recycled.

----

5. Lithium cells have a higher energy density than traditional cells.

Lithium cells have a higher energy density than traditional cells, which means they are able to store more energy in less space. This makes lithium cells more compact and lighter than traditional cells.

-----

6. Lithium cells are versatile and used in a variety of applications.

Lithium cells are used in a variety of applications, from powering portable devices to electric vehicles to power systems for homes and businesses. Due to their long life, efficiency and compactness, lithium cells are becoming more and more popular

----

Lithium cells have a long service life compared to other types of cells, such as lead-acid. Their performance and capacity remain stable for many years, making them more cost-effective in the long run.

------

strong>2. Lithium cells require special handling during transport.

Lithium cells require special handling during transport due to their unique construction and potential risk of explosion if damaged. Depending on the regulations in your country, there are specific requirements for transporting lithium cells.

------

3. Lithium cells are increasingly popular in automotive applications.

Lithium cells are increasingly popular in automotive applications because they offer higher efficiency and capacity than traditional cells such as lead-acid. Electric cars equipped with lithium fire are more ecological and cheaper to maintain than traditional vehicles with internal combustion engines.

-----

4. Lithium cells are greener than traditional cells.

Lithium cells are greener than traditional cells because they do not contain toxic substances such as mercury, cadmium or lead that are present in other types of cells. In addition, most of the materials used in the production of lithium cells can be recycled.

----

5. Lithium cells have a higher energy density than traditional cells.

Lithium cells have a higher energy density than traditional cells, which means they are able to store more energy in less space. This makes lithium cells more compact and lighter than traditional cells.

-----

6. Lithium cells are versatile and used in a variety of applications.

Lithium cells are used in a variety of applications, from powering portable devices to electric vehicles to power systems for homes and businesses. Due to their long life, efficiency and compactness, lithium cells are becoming more and more popular

----

Connection Types of "PV" Solar Panels

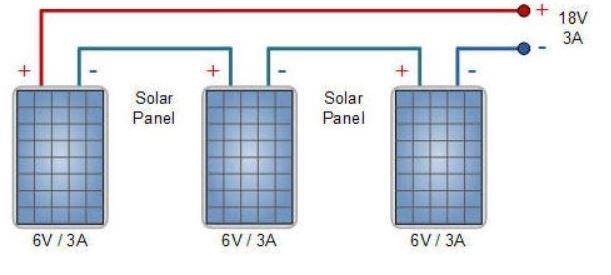

Here is a description of the three different connection types of photovoltaic (PV) panels:

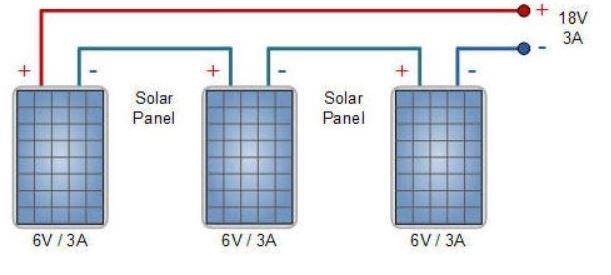

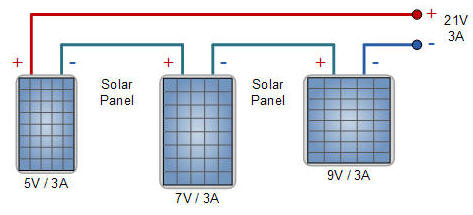

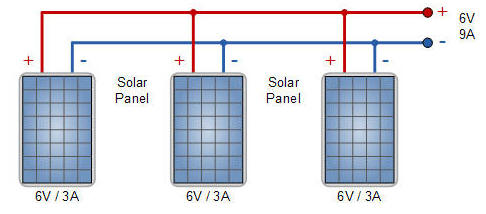

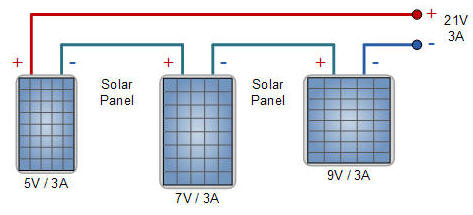

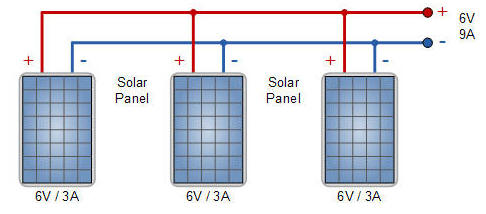

1. Series connection: In this type of connection, the PV panels are connected in a chain in which electricity flows through each panel in sequence. The series connection increases the total voltage generated by the panels while the current remains constant. This connection is commonly used in high-voltage systems such as photovoltaic power plants.

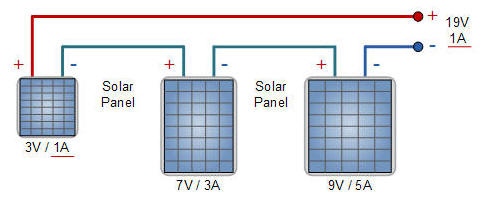

2. Parallel connection: In this type of connection, the PV panels are connected in parallel so that each panel is connected to a common power line. Parallel connection increases the total current that can be drawn from the panels while the voltage remains constant. This connection is commonly used in low-voltage systems, such as photovoltaic installations on the roofs of houses.

3. Series-parallel connection: This connection is a combination of series and parallel connections. In such a connection, several groups of PV panels are connected in series and each of these groups is connected in parallel. This allows you to increase both voltage and current. This connection is often used in medium voltage systems such as solar power plants on the ground.

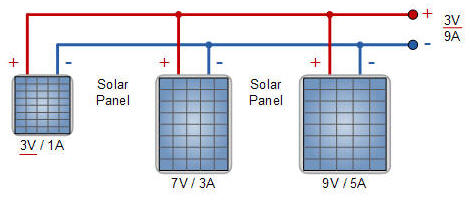

Current Mismatch of "PV" Panels

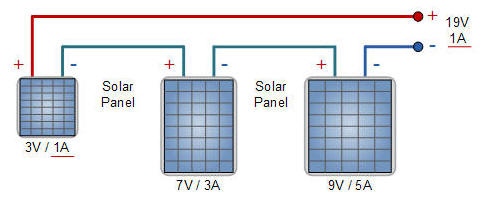

When designing the layout of the panels on the roof and the way they are connected in chains (strings), it should be remembered that in a series connection of panels, the voltages of individual modules add up and the resultant current is equal to the current flowing through the "weakest" panel in the chain. br>

1. Series connection of PV panels and the same current-voltage characteristics.

img alt="" src="https://static.s123-cdn-static-d.com/uploads/7202780/2000_64038e4e64b23 .png" class="fr-fic fr-dii">

2. Series connection of panels with different voltage characteristics but identical current characteristics.

3. Series connection of panels with different current and voltage characteristics.

-------------

1. Parallel connection of PV panels and the same current-voltage characteristics.

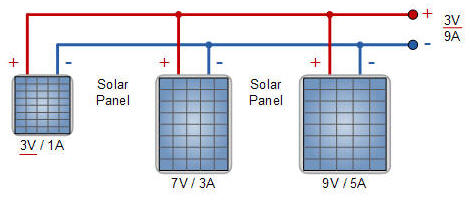

2. Parallel connection of panels with different current-voltage characteristics.

If at least one panel in the chain will have different characteristics (shading, damage, surface, etc.), the efficiency of the entire chain will be different, but in total greater than with serial connection.

--------------------------- ------------------

It follows that when it is necessary to connect different modules with different current-voltage characteristics caused by e.g.

- replacing a damaged module

- expanding the PV installation

- connecting modules from different manufacturers

- connecting modules of different sizes

Parallel connection is a more advantageous solution.

Generally, you should not:

– connect modules with different current characteristics in series

– connect modules with different voltage characteristics in parallel

----------------------------

1. Series connection of PV panels and the same current-voltage characteristics.

img alt="" src="https://static.s123-cdn-static-d.com/uploads/7202780/2000_64038e4e64b23 .png" class="fr-fic fr-dii">

2. Series connection of panels with different voltage characteristics but identical current characteristics.

3. Series connection of panels with different current and voltage characteristics.

-------------

1. Parallel connection of PV panels and the same current-voltage characteristics.

2. Parallel connection of panels with different current-voltage characteristics.

If at least one panel in the chain will have different characteristics (shading, damage, surface, etc.), the efficiency of the entire chain will be different, but in total greater than with serial connection.

--------------------------- ------------------

It follows that when it is necessary to connect different modules with different current-voltage characteristics caused by e.g.

- replacing a damaged module

- expanding the PV installation

- connecting modules from different manufacturers

- connecting modules of different sizes

Parallel connection is a more advantageous solution.

Generally, you should not:

– connect modules with different current characteristics in series

– connect modules with different voltage characteristics in parallel